Erro de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Equipos de sala limpa

Os equipos limpos son cruciais para manter a esterilidade e limpeza de ambientes controlados, garantindo a calidade e fiabilidade dos produtos fabricados nestes espazos. Deseñado para soportar as demandas de rigorosos estándares de sala limpa, os equipos limpos abarcan unha serie de ferramentas e máquinas especializadas adaptadas para satisfacer as necesidades únicas de varias industrias.

No núcleo dos equipos de sala limpa atópanse a súa capacidade para evitar a contaminación de partículas. Isto conséguese mediante o uso de filtros de aire de partículas de alta eficiencia (HEPA), que eliminan o 99,97% das partículas que miden 0,3 micrómetros ou maiores do aire. Estes filtros son empregados en sistemas de purificación de aire, asegurando que o ambiente de limpeza permaneza libre de po, lixo e outros contaminantes que poidan comprometer a calidade do produto.

Os equipos limpos tamén inclúen unha serie de ferramentas e estacións de traballo especializadas deseñadas para minimizar a xeración de partículas. Por exemplo, os bancos de traballo certificados con salas limpas están equipados con superficies lisas e non porosas que resisten á acumulación de po e sucidade. Do mesmo xeito, a roupa e os accesorios aprobados por cuartos limpos, como abrigos de laboratorio, luvas e cubertas de zapatos, están feitos a partir de materiais libres de peluxe e fáciles de limpar.

Ademais do control de partículas, os equipos limpos tamén deben abordar o problema da contaminación microbiana. Isto conséguese mediante o uso de luces UV e outras técnicas de esterilización, que matan ou inactivan microorganismos que poden estar presentes no ambiente do cuarto limpo.

En xeral, o equipo de sala limpa é un compoñente crucial de calquera ambiente controlado, garantindo a esterilidade e limpeza necesaria para a produción de produtos fiables de alta calidade. Ao investir en equipos de alta calidade, as empresas poden maximizar a súa eficiencia operativa, reducir os residuos e asegurar a satisfacción dos seus clientes.

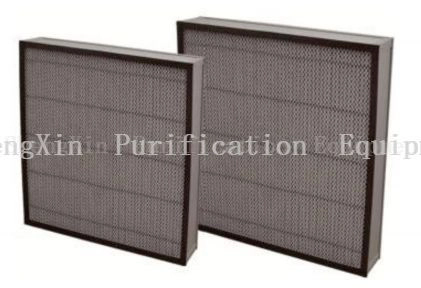

Filtro HEPA

Os filtros HEPA de deshengxin captan de xeito eficiente o 99,997% dos contaminantes no aire tan pequenos como 0,3 micras, proporcionando unha solución completa de aire limpo. Os nosos filtros eliminan unha ampla gama de partículas, incluíndo bacterias, esporas de moldes, hollín, polenes, cabelo animal, dander, ácaros de po, partículas de fume e outros alérgenos e partículas que danan os pulmóns. Utilizando papel de filtro de fibra de vidro H13-H14, estes filtros ofrecen niveis de eficiencia excepcionais de H13: 99,97-99,99% @ 0,3um e H14: 99,99% @ 0,3um (MPPS). As opcións de marco personalizables inclúen caixas de perfil de aluminio, caixas de plegamento de aluminio, caixas galvanizadas e caixas de aceiro inoxidable. Cada filtro está equipado cunha rede de protección en forma de diamante pintada en po e selada con neopreno para maior durabilidade. Dispoñibles en varios grosores do perfil de aluminio que oscilan entre os 46 mm e os 96 mm, os nosos filtros atenden a necesidades específicas do cliente. Adecuado para aplicacións en fábricas ultra-limpo, a industria dos semicondutores, a investigación da forza atómica, as salas limpas, as capucha laminar, os bancos limpos e moito máis.

Filtro químico FFU

O filtro químico de Deshengxin FFU (Unidade de Filtro de ventilador) é un sistema de purificación de aire de última xeración deseñado para eliminar de xeito eficiente unha ampla gama de contaminantes do aire interior. Utilizando a tecnoloxía de filtración de punta, o noso filtro químico FFU é capaz de eliminar ácidos, alcalís, condensados e outros contaminantes implantados, garantindo un ambiente de traballo limpo e saudable. A medida para industrias como semiconductores, laboratorios e instalacións médicas, os nosos filtros ofrecen un rendemento versátil e opcións personalizables para satisfacer as necesidades específicas de tratamento aéreo. Con comprobacións de calidade rigorosas, estabilidade fiable e apoio profesional do equipo, os filtros químicos de Deshengxin FFU proporcionan unha solución perfecta aos retos de contaminación, contribuíndo a un espazo interior máis seguro e máis limpo.

Filtro químico AMC PLEAT PLEAT plano para unidades de aire acondicionado (MAU)

O filtro químico de Deshengxin FFU (Filtro Filtro de ventilador) é un dispositivo avanzado de purificación de aire deseñado para eliminar de xeito eficiente unha variedade de contaminantes do aire interior. Utilizando a tecnoloxía de filtración de punta, este filtro é capaz de eliminar ácidos, alcalinos, condensados e outros contaminantes implantados, garantindo un ambiente de traballo limpo e saudable. Está especialmente adaptado para industrias como semiconductores, laboratorios e instalacións médicas, ofrecendo un rendemento versátil e opcións personalizables para satisfacer as necesidades específicas de tratamento aéreo. O filtro químico de Deshengxin FFU conta con medios de filtración avanzados que captan efectivamente pequenas partículas e contaminantes, proporcionando aire interior máis limpo. Tamén inclúe capacidades de eliminación de olores, neutralizando e eliminando varios cheiros para garantir un ambiente interior máis agradable e cómodo. Con alta capacidade de adsorción, reduce a frecuencia das substitucións de filtros, reducindo os custos e aforro de man de obra. A instalación sinxela, deseñada para a maioría dos equipos estándar de aire acondicionado, convérteo nunha solución de filtración de aire cómoda e eficaz. Con comprobacións e probas de calidade rigorosas, o filtro químico Deshengxin FFU ofrece estabilidade e durabilidade fiables para o funcionamento a longo prazo. Ofrece aos clientes unha garantía continua de eliminación de contaminación e reduce os custos de mantemento operativo. O noso equipo profesional posvenda ofrece servizos de mantemento técnico e mantemento técnicos oportunos, asegurando que o produto permaneza en condicións de traballo óptimas e proporcionando garantía completa do servizo aos usuarios.

Copia do sistema de ventilación

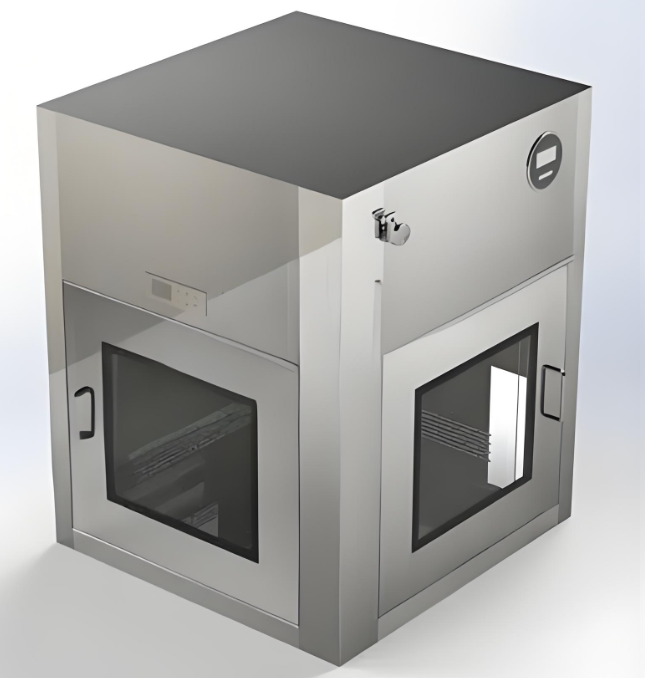

The VHP Pass-Through Box is an advanced sterilization solution designed to maintain sterile environments within pharmaceutical, biotechnology, and healthcare facilities. Utilizing vaporized hydrogen peroxide (VHP) as the sterilant, this box ensures thorough and efficient disinfection of all materials passing through it. Crafted with precision and attention to detail, the VHP Pass-Through Box adheres to the strictest industry standards, featuring a seamless stainless steel construction that is easy to clean and highly resistant to corrosion. The box incorporates cutting-edge technology to guarantee optimal sterilization and decontamination, with automated operation that simplifies the process and ensures consistent, repeatable results. Its flexible configuration allows for adjustable chamber sizes and customizable settings, accommodating a wide range of item sizes and shapes. The intuitive control system provides easy monitoring and control of the sterilization process, with operators able to set parameters, monitor progress, and receive notifications for completion or potential issues. In addition to its efficient sterilization capabilities, the VHP Pass-Through Box is also known for its material compatibility, gentleness on various materials including plastics, metals, and rubber, without damaging their integrity or functionality. The VHP process breaks down into water and oxygen after sterilization, leaving minimal toxic residuals and contributing to sustainable practices by minimizing the need for hazardous waste disposal. Overall, the VHP Pass-Through Box is a robust and reliable solution for industries requiring high-level disinfection and sterilization. Its combination of efficiency, material compatibility, environmental friendliness, automation, flexibility, and safety features make it an ideal choice for maintaining sterile environments in critical facilities. Contact us today to learn more about how our VHP Pass-Through Box can benefit your operation.

VHP Pass-Through Copy

The Corner Pass-Through Box, a specialized transfer device, features a unique corner design enhancing spatial flexibility. Constructed of two sealed chambers with adapted door mechanisms, it optimizes item transfer in limited spaces, reducing contamination and enhancing efficiency. With excellent sealing, interlock safety features, and intercom communication, it ensures safe, clean, and efficient operations. Designed for ease of cleaning and maintenance, it adapts to diverse environments like electronics factories, pharmaceutical plants, and labs. Its primary purpose is to control contaminant spread, making it ideal for air-purified settings such as LCD factories, hospitals, and food processing industries.

Caixa de pase dinámico de sala limpa / caixa de caixa de paso GMP

The DSX Mechanical Interlock Pass Box is a state-of-the-art cleanroom equipment designed to facilitate the secure and contamination-free transfer of materials between different environments. Crafted with precision and durability in mind, this pass box features a robust stainless steel construction and a mechanical interlocking system that ensures both doors cannot be opened simultaneously, thereby maintaining the integrity of the cleanroom environment. With its high filtration efficiency and customizable size options, the DSX Mechanical Interlock Pass Box is an essential tool for industries that require stringent contamination control, such as pharmaceuticals, biotechnology, and electronics manufacturing. Trust Deshengxin for a reliable and efficient cleanroom solution that meets your specific needs.

Copia de caixa de pase mecánico de intercambio mecánico

The Air Shower Pass Box with Automatic Roller Conveyor is an advanced material transfer system designed for use in cleanroom environments. It seamlessly integrates an air shower with an automatic roller conveyor to ensure efficient, contamination-free transfer of materials between different cleanliness zones. The automatic roller conveyor simplifies the loading and unloading process, reducing manual handling and minimizing the risk of cross-contamination. The air shower function, equipped with high-efficiency filters, effectively removes particles and contaminants from the surface of items, maintaining the cleanliness of the cleanroom. Suitable for various industries such as pharmaceuticals, biotechnology, and microelectronics, this innovative pass box offers a customizable design to meet specific requirements and enhance operational efficiency. With its robust construction and user-friendly features, the Air Shower Pass Box with Automatic Roller Conveyor is an essential tool for maintaining hygiene and sterility in high-standard work environments.

Caixa de paso de ducha de aire con copía de transportadores automáticos

This advanced system combines the precision of automatic induction technology with the convenience of a conveyor belt, creating a seamless and efficient process for moving items between different areas while maintaining strict contamination control. The DSX system features an automatic lift door that operates with remarkable accuracy, detecting the presence of items and opening/closing with minimal delay. This ensures a rapid and secure transfer, minimizing downtime and maximizing productivity. The integrated conveyor belt further enhances the system's efficiency, allowing for effortless movement of items from one side to the other, reducing manual handling and eliminating the risk of human error. Crafted from high-quality materials, the DSX Automatic Induction Lift Door Pass Through Box with Conveyor is built to last. Its robust construction and precision engineering ensure that it maintains its performance and reliability over time, even in the most demanding applications. Whether you're in the pharmaceutical, electronics, food processing, or any other industry that requires stringent contamination control, the DSX system offers a tailored solution to meet your unique needs. Its modular design allows for easy integration into existing operations, ensuring a smooth transition and minimal disruption to your workflow. In summary, the DSX Automatic Induction Lift Door Pass Through Box with Conveyor is the ultimate choice for efficient, reliable, and contamination-free material transfer in controlled environments. Experience the future of material handling today with the DSX system.

Caixa de caixa de dobre porta-Copia

Introducing the DSX Electronic Interlock Pass Box, a revolutionary solution designed to revolutionize the way materials are securely transferred between cleanrooms. Engineered with precision and innovation, this pass box features an advanced electronic interlock system that guarantees both doors cannot be opened simultaneously, thereby preventing cross-contamination and maintaining the integrity of sensitive environments. Crafted from high-quality stainless steel, the DSX Electronic Interlock Pass Box offers exceptional durability and ease of maintenance. Its sleek and smooth surface facilitates effortless cleaning, ensuring it remains in pristine condition over time. With a range of customizable options available, the DSX Electronic Interlock Pass Box can be tailored to suit specific requirements. From UV sterilization and air ionization to various configurations like window type, desktop type, and floor type, this pass box offers unparalleled flexibility and adaptability. Furthermore, the DSX Electronic Interlock Pass Box boasts an emergency stop button for immediate shutdown in case of emergencies, ensuring operator safety and system reliability. Suitable for a wide range of industries, including pharmaceuticals, biotechnology, semiconductors, food industry, hospitals, data centers, manufacturing plants, and research and development settings, this pass box is a must-have for any organization prioritizing contamination control and secure material transfer. Discover the DSX Electronic Interlock Pass Box today and experience the ultimate in secure, efficient, and reliable material transfer solutions.

Copia electrónica de pase de intercambio

Meet the DSX Advanced Air Shower Pass-Through Box, a top-tier solution for enhancing cleanliness and sterility in controlled environments. Constructed from durable stainless steel, this system employs high-velocity air jets filtered through HEPA/ULPA filters to scrub contaminants from surfaces. Its modular design allows for easy customization, while adjustable airspeed and airflow direction optimize the decontamination process. Additional features like UV sterilization and air ionization can be included for enhanced performance. The DSX Air Shower Pass-Through Box features secure access control, transparent viewing windows for monitoring, and energy-efficient operation. Suitable for industries like pharmaceuticals, biotechnology, semiconductor manufacturing, and more, this system ensures cleanliness and sterility in critical environments.